Engine-pedia: the GM Atlas is the next big swap platform

For years, the gold standards in high-performance inline-six engine swaps have been the Toyota 2JZ (Supra) and the Ford Barra (Falcon). However, as the supply of these legendary engines dwindles and their prices soar, performance enthusiasts are desperately searching for the "next big thing."

This is where the GM Atlas family, especially the flagship 4.2L inline-six (LL8), steps in. With a massive 4.2-litres of displacement—significantly larger than many contemporaries—and an all-aluminum construction that contributes to a relatively light weight, the LL8 is a torque monster straight from the factory. Crucially, these engines are abundant and inexpensive due to their use in mass-market SUVs. Coupled with a notoriously strong bottom end and generous 108.0mm bore spacing, the Atlas I6 provides an exceptionally affordable, high-capacity, and durable platform ripe for forced induction builds, making it the premier budget-friendly option for swaps today.

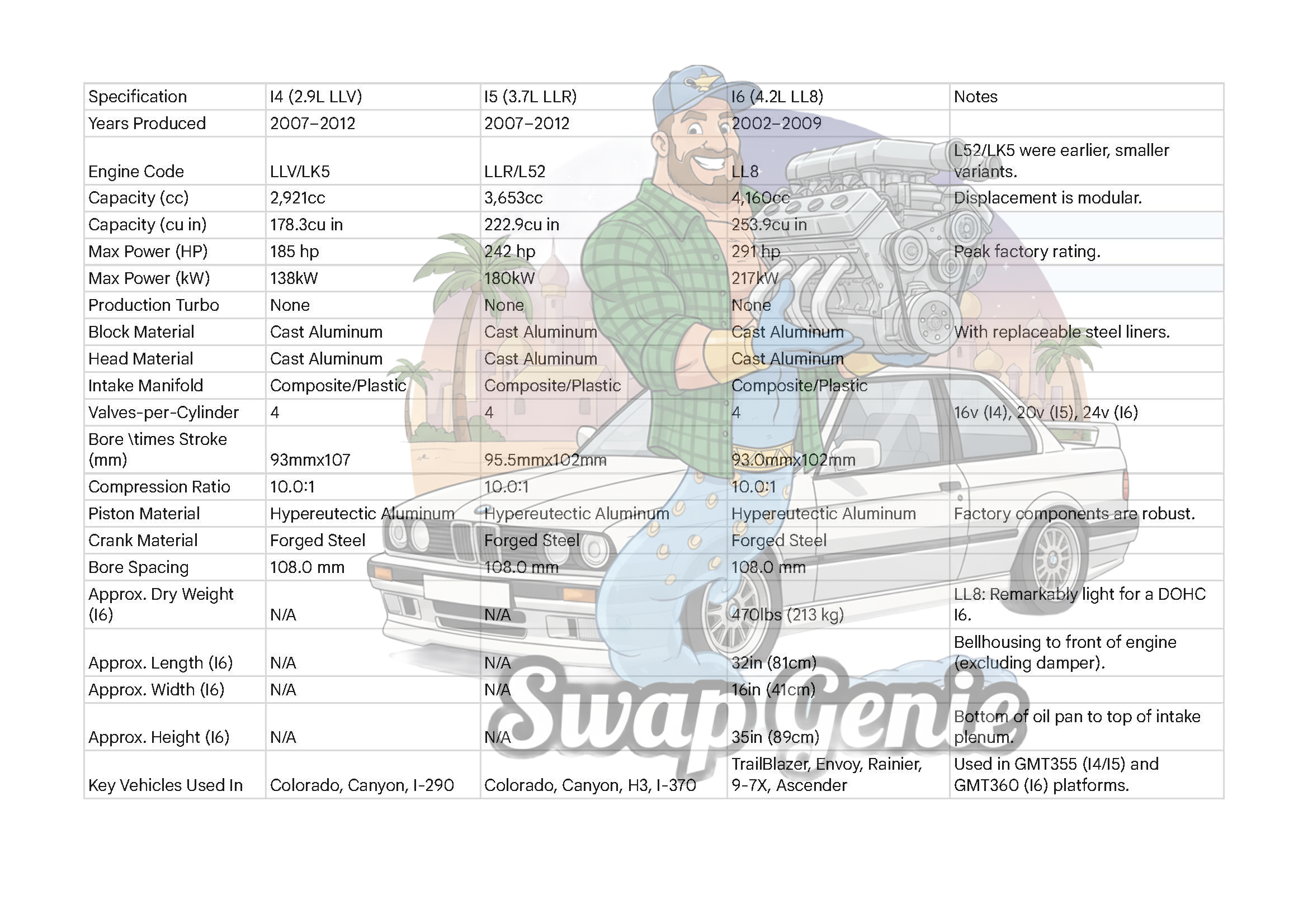

The General Motors Atlas engine family represents a significant and ambitious mid-2000s engineering effort to create a modular, high-output line of inline engines (four, five, and six cylinders) sharing a common architecture. Conceived to replace older pushrod I4 and V6 designs in light trucks and SUVs, the Atlas family—particularly the legendary 4.2L I6 (LL8)—garnered a reputation for smooth, reliable power and surprising strength, earning it the nickname "Ameri-Barra" or "American 2JZ" among enthusiasts.

A core design choice for weight savings, using a cast aluminum block with replaceable steel cylinder liners, and an aluminum DOHC cylinder head contributes significantly to the Atlas engines’ relative low weight, especially the LL8.

All Atlas engines feature a DOHC head with 4-valves-per-cylinder (16V for I4, 20V for I5, 24V for I6), lending it deep-breathing capabilities. A crucial feature for emissions and power delivery, Atlas engines employed VVT on the exhaust camshaft only, allowing a 25-degree range of adjustment. This VVT system helped the engine meet stringent emissions standards without needing an Exhaust Gas Recirculation (EGR) system. Atlas engines also benefit from a modern coil-on-plug ignition system for precise timing and reliable high-voltage spark delivery.

One of the most defining and robust technical features of the Atlas family is its generous capacities for use in truck platforms. Coupled with the all-aluminum block these huge displacements are key to the engines’ ability to handle massive big hot rod power and boost levels, with the 108mm bore-spacing also providing ample material integrity between cylinders to let the boost flow.

The LL8 inline 6 engine was on sale between 2002 and 2009 and offered between 270hp (201kW) and 291hp (217kW) with up to 277lb-ft of torque, making it a robust, light and capable 6-cylinder engine.

The Atlas LL8's unique dimensions and bellhousing pattern make it both challenging and highly desirable for engine swaps. While being an inline engine makes it narrow, the LL8 is notably tall (35inches) and long (32inches) compared to a GM LS V8. This height can cause clearance issues with the hood in many traditional RWD platforms (like muscle cars or smaller trucks), often requiring a modified intake manifold or a custom hood scoop.

The factory oil pan is a large front sump design with a pass-through channel for the front differential of the GMT360 platform (TrailBlazer/Envoy). For swaps into classic rear-wheel drive (RWD) vehicles (like Foxbody Mustangs or older hot rods), this front sump configuration usually interferes with the steering rack or crossmember, making a custom, rear-sump oil pan a necessary modification.

The Atlas I6 (LL8) is particularly appealing due to its transmission interface, which simplifies swaps into RWD platforms:

While the LL8's crankshaft bolt pattern is unique, the engine block uses the ubiquitous GM V8 Small-Block Chevy (SBC) bellhousing pattern (also shared by LS, BBC, and earlier V8s). This is a critical factor for swaps. Due to the LL8's unique starter location, a specialised adapter plate kit (available from suppliers like Performance Adapters) is required to successfully mate the LL8 to common GM V8 transmissions like the 4L80E, which is the recommended automatic for forced-induction builds due to its inherent strength and reliability, easily handling 500 hp.

The premier manual transmission choice is a T56 or TR6060 Tremec, adapted using the V8 bellhousing pattern and the necessary Atlas adapter kit. However, the Aisin AR5 (GM MA5) 5-speed manual, found in the smaller Atlas I4/I5 vehicles (Colorado/Canyon), can be mated to the LL8 via specific swap parts. Its bellhousing shares a crucial bolt pattern with the Toyota R154, making it an affordable, strong, and highly adaptable manual option popular among import swappers.

The Atlas family evolved in two main generations: the initial variants (LL8, L52, LK5) and the later, slightly larger-displacement versions (LLR, LLV, LL8/Vortec 4200 final tune).

The 4.2L LL8 was the first and most powerful Atlas engine. It featured a long stroke of 102 mm combined with a 93 mm bore, resulting in a slightly under-square design that prioritised torque delivery, with nearly 90\% of peak torque available from 1,800RPM.

The inline-five cylinder variants (3.5L L52 and later 3.7L LLR) were essentially the LL8 with one cylinder removed. This configuration presented unique challenges in balance, which GM mitigated by incorporating dual balance shafts running in the crankcase.

The inline-four variants (2.8L LK5 and 2.9L LLV) also used dual balance shafts and were used in lighter-duty applications, primarily the smaller GMT355 platform.

Overall, the Atlas family is considered highly reliable, particularly the LL8 I6. However, its complex nature led to a few well-known failure points:

Water Pump Failure: The water pump is a frequently cited failure point, often needing replacement around the 80,000 to 100,000mile mark.

Cylinder Head / Valve Seat Issues (Earlier I5/I4): Early versions of the L52 (3.5L I5) and LK5 (2.8L I4) engines, particularly in the 2004–2006 Chevrolet Colorado/GMC Canyon, were susceptible to premature wear of the exhaust valve seats and/or cracks in the cylinder head due to heat. This was largely corrected with the introduction of the 3.7L LLR and 2.9L LLV.

Variable Valve Timing (VVT) Solenoid: As with many VVT-equipped engines, the exhaust cam phaser solenoid can fail or become clogged with oil sludge, leading to rough idle, reduced power, and check engine lights.

Oil Pressure Sensor: A minor, but common, fault resulting in incorrect oil pressure readings on the dash.

The Atlas engine family, especially the LL8, has a burgeoning enthusiast following, largely due to its architectural similarities to legendary Japanese and Australian inline-six engines (like the 2JZ and Ford Barra).

Unrivaled Strength: The LL8's all-aluminum block, supported by its generous 108.0 mm bore spacing, is renowned for its durability. Stock bottom ends (pistons, rods, and forged-steel crankshaft) are routinely pushed past 500 hp with bolt-on turbo kits and appropriate tuning. Heavily built versions are capable of exceeding 1,000 hp.

Packaging: Being an inline engine, it offers excellent engine bay access for maintenance and modification. It is also surprisingly compact for its displacement, especially the I5 and I4 versions, making them desirable for engine swaps into smaller vehicles.

Forced Induction Potential: While no production version was turbocharged, the high 10.0:1 compression ratio, DOHC head design, and VVT make it an excellent candidate for aftermarket turbocharging. Enthusiasts often utilize flipped factory exhaust manifolds as a cost-effective turbo manifold platform.

Availability: These engines are abundant and inexpensive in salvage yards today, having powered millions of GMT360 and GMT355 platform vehicles, making them an affordable entry point for high-power builds.